Excavators

What is an excavator?

Excavators are vehicles designed to dig, extract and/or move materials, items, and objects. These all-purpose machines are used on a huge variety of construction projects. Excavators comprise two main parts: first, a driving base complete with an enclosed driver section for operating the excavator. Second, a boom arm with an excavator bucket for scooping or extracting the materials.

Excavators are vehicles designed to dig, extract and/or move materials, items, and objects. These all-purpose machines are used on a huge variety of construction projects. Excavators comprise two main parts: first, a driving base complete with an enclosed driver section for operating the excavator. Second, a boom arm with an excavator bucket for scooping or extracting the materials.

The vehicle primarily travels along the terrain on wheels, usually on a chain wheel system. Excavators use hydraulic fluid, with hydraulic cylinders and motors, to achieve movement. In contrast, cable-operated excavators are powered by winches and steel ropes.

Excavators are used in both small and large construction projects. Cutting and filling for road construction, removal of waste, and moving construction material are common uses of excavators. Other ways these multipurpose machines are used include digging foundations, grading and landscaping, brush cutting with hydraulic attachments, placing of pipes, and mining. The huge range of available attachments make excavators a versatile and valuable piece of earthmoving equipment.

What size excavator do I need?

When choosing your excavator, consider the type of work to be done along with the size and characteristics of the worksite. You’ll want to choose an excavator that is powerful enough for the job as well as correctly sized, whether you’re moving heavy rocks or shifting pipes around.

For example, if you’re undertaking nimble excavation where you’ll need to work around existing structures and be careful around ground lines and narrow areas, a compact excavator (1.7 to 7 tonnes) could be best.

If you’re doing building and construction work, a standard excavator might be the right option for your job. Standard excavators range from seven to 45 tonnes, with the smaller ones suitable for tighter spaces and nimble work like material handling and dredging. Read our article here to find out more about which excavator is right for your needs.

Large excavators weight up to 80 tonne and are designed for heavy-duty work like mining. These machines usually need level ground and are suited to large digging jobs.

Specialist excavators are designed for specific types of jobs. For example, you might have specialist features such as a knuckle boom, or an excavator with extra-long arm joints to reach challenging areas. Zero swing excavators are suitable for confined spaces, while spider excavators have legs instead of tracks to allow them to work on different types of terrain.

You can find more information on this topic in an article on our blog here.

What is an auger driver?

Ideally suited to drilling and augering applications, and able to operate in most ground conditions, an auger driver is a precision instrument designed for digging straight downwards – creating holes that can then be used for posts, plants, or anything else that needs to be driven straight downwards into the soil.

Ideally suited to drilling and augering applications, and able to operate in most ground conditions, an auger driver is a precision instrument designed for digging straight downwards – creating holes that can then be used for posts, plants, or anything else that needs to be driven straight downwards into the soil.

To give you an idea of just how versatile an auger driver can be, people use them to drill holes in everything from soil to wood, rock and pavement to ice. The most notable feature of these devices is, of course, the large screw-shaped end that they have. This helical screw blade allows for precision as they bore into a surface, and drag the material displaced in the process out of the hole.

There are a couple of different kinds of auger driver. In terms of machine-mounted drivers (and there are handheld ones which do operate differently) there are direct drive augers that use a mounted hydraulic motor designed to provide a balance between torque and RPM – revolutions per minute. The other major kind – planetary augers – use a gear drive system that creates large amounts of torque, and are the better option for digging through difficult ground conditions.

If you are in any doubt about what kind of auger driver you need for your task, please speak to your Solution Plant Hire representative. We have a large range of auger drivers, suited to any task, and can walk you through in deciding which is best for you.

What is a ripper?

It has a name like something you’d expect to see in a horror movie, and it looks like the tooth from one of Jurassic Park’s dinosaurs, but the excavator ripper attachment is an enormously useful addition to your excavation equipment.

It has a name like something you’d expect to see in a horror movie, and it looks like the tooth from one of Jurassic Park’s dinosaurs, but the excavator ripper attachment is an enormously useful addition to your excavation equipment.

These remarkably simple tools are built with the most simple of intentions; they’re there as a tough, sharp implement to help you rip up ground. People tend to use them to make the first break into frozen ground, hard rock, or paved areas quickly and relatively noiselessly. They’re also used for digging older trees out of the ground from their roots.

They’re also remarkably simple and safe to use. They mount on the excavator using standard bucket pins and with no motorized components they are easy for just about anyone to use.

Despite that simplicity, rippers are used in construction and demolition projects of all sizes, and it’s possible to get rippers that can tear into tens of thousands of pounds of weight for really large jobs. If you have any questions about which ripper you need for a job, contact your Solution Plant Hire representative.

What is a hydraulic breaker?

A hydraulic breaker is a powerful instrument, designed for digging downwards. Once fitted to an excavator, a breaker behaves like a hammer, punching down into material that is too difficult to “crack open” otherwise. It’s often used in demolition for jobs that are too large for jackhammering, but are also unsafe for blasting (either for physical safety or environmental reasons).

A hydraulic breaker is a powerful instrument, designed for digging downwards. Once fitted to an excavator, a breaker behaves like a hammer, punching down into material that is too difficult to “crack open” otherwise. It’s often used in demolition for jobs that are too large for jackhammering, but are also unsafe for blasting (either for physical safety or environmental reasons).

Hydraulic breakers work by applying a very high pressure from a relatively small canister on the material to be broken down. There are two primary types of breakers: inner valve type and outer valve type. Regardless of the type, the basic function of the devices is the same, and the machine uses nitrogen gas to power it.

Hydraulic breakers can come in all sizes, from the small and easy to fit on a mini excavator, through to the large, heavy ones for the most difficult of tasks. Breakers are measured by their weight, with the heavier breakers designed for breaking into the thicker, heavier material. If you’re unsure of the right weight for the task that you’ve got, feel free to discuss with your Solution Plant Hire representative; we carry the full range.

These devices can be unsafe when not used properly, of course. For the sake of safety, make sure your hydraulic breaker has adequate shock absorbers on the top, which will absorb the mechanical forces and recoil energies, which can be extreme when this equipment is in operation. The shock absorbers also act to protect the equipment itself from debris and other material that might damage the components of the equipment in operation.

What is a rock saw?

There are times when what you’re trying to excavate is made of incredibly tough material. It might be that you’re digging through dense rock (which is where this attachment gets its name from), or, equally, you might need to cut through concrete, roads, or stone.

There are times when what you’re trying to excavate is made of incredibly tough material. It might be that you’re digging through dense rock (which is where this attachment gets its name from), or, equally, you might need to cut through concrete, roads, or stone.

For these jobs, the rock saw attachment comes in very handy. A rock saw is a high-powered, large saw, that gives the user a fine degree of control over what they’re doing so the job can get done safely and efficiently. That accuracy is important, as they’re generally called on to “cut out” a specific part of a rock, road, or building, without damaging the rest of the structure.

Generally, with a rock saw, you want a diamond blade, like the ones featured on Solution Plant Hire rock saws, designed to cut cleanly through any other material. The better the blade, the more precise the cut, and the better the results from the rock saw. There should also be a variety of sizes available, so that when you hire one for a specific task, it will be properly suited for it; there’s no sense using a large rock saw when the area that needs to be cut is small.

There are a couple of other features that are important in determining the quality of a rock saw. The first should be hose adaptable water fittings. It’s important that you’re able to keep the surface that you’re going to cut – as well as the rock saw itself – damp, because if the blade overheats, both the blade and the surface material can be damaged. Additionally, a good rock saw will offer an offset setting, which allows the operator to set the blade to operate on the side of the saw, providing a clear view of what’s going on for additional accuracy.

What is an Erkat twin head?

This might just be one of the most odd-looking devices that you’ll ever attach to an excavator, but don’t be misled by its strange appearance – the Erkat twin head is an enormously useful tool in a wide variety of situations.

The Erkat twin head has been designed to adapt to your different needs and can help with trenching, tunnelling, foundation, demolition, and soil mixing projects. Equally importantly, the device does its work quietly, making it a very handy attachment for areas where they are sensitivities around noise and vibration – residential areas, for example.

In operation, the Erkat twin head makes use of two hydraulic motors that generate powerful torque to cut through materials. Because of the way that these devices are designed, they’re particularly useful where accuracy in making a cut is important, and will result in a fairly smooth surface.

As an additional benefit, the waste material that is caused from the excavation when the Erkat twin head is in use will generally be fine enough that it can be used as backfill without the need for crushing; saving yet more time and expense when using this tool.

What is a Vacuworx vacuum lifting system?

As an alternative to hooks, slings and chains, many people prefer to use a Vacuworx vacuum lifting system attached to their excavator. This system is ideal for large diameter projects, such as material handling at port facilities, pipe mills, and storage yards.

As an alternative to hooks, slings and chains, many people prefer to use a Vacuworx vacuum lifting system attached to their excavator. This system is ideal for large diameter projects, such as material handling at port facilities, pipe mills, and storage yards.

As the name suggests, the system makes use of a powerful vacuum to lift materials, and this allows it to lift very heavy materials with ease; anything up to 20 tonnes if you’re using the larger models. It’s also incredibly easy to operate and can be attached and in operation in minutes. In addition to being able to handle weight, the Vacuworx can also handle quantity; the system handles up to 10 times more material than other methods would be able to.

Added to that, the Vacuworx is versatile. It allows for remote rotation to fine degrees, meaning that materials being moved by it can be placed in precise locations. For the delicate movement of objects, the Vacuworx is another indispensable tool.

Worried about whether you’ll be able to operate this device? Just speak to your Solution Plant Hire representative.

What is a sieve bucket?

A sieve bucket is an enormously useful heavy-duty tool when you’re working in an environment that has a number of different materials, and you need a screening device to help sort between those materials.

A sieve bucket is an enormously useful heavy-duty tool when you’re working in an environment that has a number of different materials, and you need a screening device to help sort between those materials.

Sieve buckets are simple in construction, but the difference in quality between them can be enormous. There are a number of things that you should be looking for when selecting a sieve bucket. Firstly, they should have strong bottom-end strength, which is important in the machine being able to carry a load across the entire width of the bucket. The shape itself is also important, as it should be designed to promote the efficient loading and sorting of material.

A good sieve bucket also has a cutting edge, to facilitate better digging of dirt, and you should also check that the ribs and apertures are of the right size to sift out the finer materials, while keeping the larger materials inside the bucket. For this reason, there are a wide range of different sieve buckets available, which can sort through materials on just about any work site.

It is crucial that the sieve bucket will be functional on a wide range of different worksites, and can handle hot materials, such as steel slag. It is an indispensable part of any worksite, as it allows you to do the kind of sorting that would be inefficient – or even dangerous – manually.

What is a rock grab?

Rock grabs have a pretty self-explanatory name; they’re there to grab and move large rocks around. Though they might sound quite elementary for use with an excavator, they are of critical importance, so making sure you’re using a good one is important.

Rock grabs have a pretty self-explanatory name; they’re there to grab and move large rocks around. Though they might sound quite elementary for use with an excavator, they are of critical importance, so making sure you’re using a good one is important.

Rock grabs actually require a great deal of precision in construction in order to make sure that they’re able to operate in the field as intended. For example, a good rock grab needs to be designed to be properly balanced; a poorly balanced one will struggle to grip and move objects around.

Rock grabs should also be robust, with wear resistance on the fingers of the device. A rock grab that has worn away at the fingers will lose its grip, and is unable to operate to full efficiency. In order to maintain strength, a rock grab’s pivot pins should be hardened, and the finger tine tips should be replaceable.

In the field, a rock grab will be put through a lot of weight distribution. That means that whatever the device is picking up and moving will shift around as it’s twisted and turned. Without a very robust design, it’s easy for rock grabs to become warped and twisted. This is why you should only hire rock grabs that you can be sure are market-leading in construction, so that when you’re using them in the field, you can be sure they’ll operate as intended.

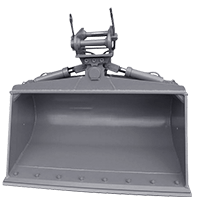

What is a tilt bucket?

The humble tilt bucket attachment might just be the most iconic piece of equipment that people use on their excavators. It’s a timeless tool that is designed to make the process of trenching and digging a snap, and no work site is complete without one.

The humble tilt bucket attachment might just be the most iconic piece of equipment that people use on their excavators. It’s a timeless tool that is designed to make the process of trenching and digging a snap, and no work site is complete without one.

A good tilt bucket should feature two key things. Firstly, it should be shaped in just the right way to maximise the digging effectiveness of the bucket. There should be a sharp ridge on the edge to help the bucket penetrate the soil material. From there the bucket should be tilted at 45 degrees, which is the perfect angle for digging, while also keeping the material collected in the bucket.

The best tilt bucket attachment should also feature a hydraulic design. This, more technically advanced approach to bucket design will allow you far greater control over the bucket in operation, allowing you to achieve finer and more intricate results.

As one of the most in-demand attachment tools for excavators, we know how important the tilt bucket is on the worksite, and your Solution Plant Hire representative will be able to help you select the bucket that is right for the job you’ve got planned.

What is a crusher bucket?

Disposing of unwanted material is a critical part of any construction or demolition job, and for these tasks the crusher bucket is indispensable. The line of crusher buckets that we have at Solution Plant Hire have been used for demolition, excavation, recycling, quarries, mines, roadworks, and piping.

Disposing of unwanted material is a critical part of any construction or demolition job, and for these tasks the crusher bucket is indispensable. The line of crusher buckets that we have at Solution Plant Hire have been used for demolition, excavation, recycling, quarries, mines, roadworks, and piping.

Having a crusher bucket on site helps keep the costs of the project under control; instead of needing to continuously ship waste material off site for disposal, you’ll be able to manage the process on-the-go.

Where many crusher buckets are built poorly and damage the excavator in operation, our crusher buckets have been designed specifically for heavy and frequent use, so as to reduce strain on the excavator arm. As an additional benefit to this, the buckets cause minimal vibrations, which is important when working in areas that are sensitive to noise and vibration, such as domestic environments.

Using a crusher bucket safely requires that you carefully read the manual, and have a chat with your Solution Plant Hire expert to make sure you’re comfortable with the device before beginning operation.

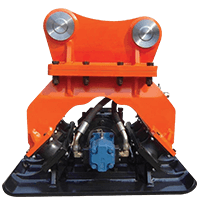

What is a compaction plate?

Compaction plate excavator attachments are incredibly useful tools for worksites, in helping to “neaten” an area that has been disturbed through work by flattening and smoothing the area. There are a wide range of compactor plates on the market; some are used by hand while others can be attached to an excavator to complete larger tasks.

Compaction plate excavator attachments are incredibly useful tools for worksites, in helping to “neaten” an area that has been disturbed through work by flattening and smoothing the area. There are a wide range of compactor plates on the market; some are used by hand while others can be attached to an excavator to complete larger tasks.

Compaction plates for excavators are incredibly useful tools because they are so versatile. You might need to get into a narrow trench or large backfill, but you also might be working with vertical and inclined compaction, and for those tasks you’ll absolutely need to be working with an excavator and compaction plate attachment.

Another benefit of working with a compaction plate on an excavator is that it is easy to operate. Though you’ll need to be familiar with working with excavators themselves, of all the tool attachments, the compaction plate is the most straightforward and safe in operation.

So what makes a good compaction plate? It should feature a multi-setting, 360º swivel head attachment, to ensure maximum versatility on the job. Additionally, a compaction plate will be designed in such a way that pressure exerted by the boom on the top plate causes the mounts to convert from shear to compression mode. For more information, discuss with your friendly Solution Plant Hire expert your compaction requirements.

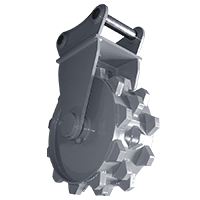

What is a compaction wheel?

A compaction wheel attachment is a heavy mechanical tool designed to reduce the size of waste material or soil through compaction. The benefit of a compaction wheel on the worksite is that it reduces costs through efficiency (it would take far longer to do its task manually), and it works equally well across flat and sloped surfaces.

A compaction wheel attachment is a heavy mechanical tool designed to reduce the size of waste material or soil through compaction. The benefit of a compaction wheel on the worksite is that it reduces costs through efficiency (it would take far longer to do its task manually), and it works equally well across flat and sloped surfaces.

In terms of what you’re looking for in a compaction wheel, there are a couple of key elements to consider. It should be rated to work effectively in all soil types, regardless of whether the soil is granular (sand-like) or cohesive (mud-like). It should also be made of a high strength steel, and have high quality roller bearings. Naturally a compaction wheel needs to be free to roll by design.

A compaction wheel should also be easy to clean, as one that allows for the buildup of dirt and debris can, even over the period of a single job, degrade in quality.

The benefit of a compaction wheel is that it can be an incredibly versatile device on the worksite. Just about any construction environment, from landscaping at home to the construction of a high rise building, will be in need of compaction, and the wheel is an innovative and time efficient way to achieve this.

Posi track

What is a posi track?

Posi tracks, like excavators, are used to collect earth and other materials. You can use posi tracks to spread and load materials. However, posi tracks work quite differently from an excavator because they pull the dug-out debris back towards the body of the vehicle, making posi tracks more fixed in movement than excavators.

If you’re considering using a posi track, note you’ll need enough room to move the vehicle for it to be effective. For example, while excavators have a 360-degree rotation capability, posi tracks have an operating radius of 200 degrees to the left and right. If you have plenty of space to move, this won’t be a problem. For example, you can easily use a posi track to dig holes in a row as long as you’ve got plenty of room to move the posi track between the holes.

Note you can expand the functionality of a posi track by adding a range of hydraulic attachments. You can use a tilt rotator, grapple, breaker, auger, or some other type of attachment to enhance digging, drilling, and carrying capabilities.

What is a posi track broom?

Posi track brooms are attachments you add to a posi track to enhance the machine’s sweeping functionality. A broom attachment typically gives posi tracks the ability to sweep flush to a curb or wall to the right. Some brooms are designed for pickups, while others are suitable for sweeping jobs.

These brooms might come with high-torque motors, making them appropriate for heavy materials. Brooms can range in size, sweeping width, and brush diameter, and these varying specifications can make certain models more suited to specific jobs. Typically brooms are used to sweep away and remove construction material like rock, stone, gravel, mud, and sand.

What is a pallet fork?

Pallet forks are attachments for forklifts or track loaders that can be used to carry heavy loads of materials around construction sites. Versatile and multifunctional, this type of attachment can also be used for landscaping projects, industrial plant work, and any other type of site requiring heavy items to be moved around.

Usually powered with a hydraulic system, pallet forks can be used to lift, carry, and set down heavy loads around the worksite. The operator of the forklift can adjust the setting on the pallet fork inside the forklift or track loader. High quality pallet forks might come with a precision mounting plate to ensure accurate and stable attachment.

What is a harley rake?

Harley rakes are tractor attachment tools designed to dig in or agitate shallow soil. Also known as soil conditioners, Harley rakes resemble garden rakes without the handle. The rake itself is drum shaped with teeth (like garden rakes) to help break up and even out soil. Unlike some self-powering attachments, Harley rakes draw power from the tractor.

Common uses for this type of attachment include soil conditions on large-scale projects or re-turfing. Since digging and agitating soil is used in many construction, farming and forestry processors, you’ll find everyone from farmers and landscapers to construction workers using Harley rakes. However, while Harley rakes can be effective with grass and small brush, rocks and tree roots are more suited to other types of attachments. You might find this equipment useful other projects like highway widening and agricultural field preparation.

What is a trencher?

Trenchers are attachments for posi tracks, excavators and other construction machinery. They’re designed to provide precision depth control so you can control how deep you’d like to dig. These hardy attachments can be used on any type of soil, even tough, rocky soil types. If you’re digging close to a building or fence, look for a trencher with a side-shift feature to avoid damaging the fencing or building. Different teeth and chain options can be used out to improve digging outcomes in different soil conditions.

High-quality trenchers can be designed to work as much as four times faster than a conventional digging bucket while giving you a cleaner finish. Since precision digging is a common type of job, trenchers can used by anyone from maintenance crews and landscapers to utility companies and construction workers.

What is a grapple bucket?

Grapple buckets are skid steer attachments designed for vehicles such as posi tracks or mini loaders. This type of attachment incorporates a bucket and a jaw-like top attachment, allowing the operator to securely transfer loads over the worksite. The bottom part of the attachment scoops up debris while the large teeth of the top half ensure you achieve a good grip. Designed for extremely heavy-duty jobs, grapple buckets can be used on construction sites as well as landscaping jobs.

Common jobs for grapple buckets include clearing branches and bushes, and moving heavy rocks and rubble. With a grapple bucket, you can easily carry awkwardly-shaped, heavy items like rocks, pieces of concrete, and logs. The top jaw-like cover, which closes over the bottom half, can reduce the risk of tipping or falling out of loads in the bucket.

Other construction site equipment

What is a watercart?

Watercarts are large trucks with water tanks and water dispersing features. They’re used for mining, construction, and other operations. Typically they’re used for dust control and compaction, but water carts can also prove useful for fire prevention.

In parts of Australia, dust can be a major challenge for worksites and mining operations, and can be a serious health hazard for workers. Spraying dry earth and surfaces with water is an effective way to counter dustiness on worksites. In addition, damp soil can be easier to compact than dry soil, so water carts are also used for soil compaction on construction sites. And during the hottest months of the year, preventative spraying can reduce the risk of fire.

What makes watercarts different from standard trucks are their special tanks, custom chassis design, mountain apparatuses, and pumping capabilities. Watercarts can range from 5,000 litres to upwards of 10,000 litres in capacity.

Some watercarts are designed to haul large loads of water over rugged terrain. They usually come with filler pipes and spray nozzles, and the driver might be able to operate the spray mechanism. Other features might include drop bars, water cannons, and hose reels.

What is a site dumper?

Construction site dumpers are vehicles used for carrying bulk items. Commonly seen on building and construction sites, dumpers are usually powered by diesel, and should not be mistaken for dump trucks. Dump trucks usually have their loads situated behind the cab, while dumpers feature an open load or skip at the front of the vehicle. Dumpers tend to be smaller and more mobile, making them suitable for smaller loads and jobs.

The operator of the dumper uses the skip to pick up loads and then tips the skip to dump the load. You can add a towing eye to use dumpers as site tractors. Other accessories include rubber tracks, which can give you a more even weight distributions over challenging terrain. Dumpers can usually carry up to 10 tonnes per load.

What is a roller?

Rollers are large vehicles used to compact surfaces. Sometimes known as roller-compactors, they can be used to compact soil, gravel, concrete, asphalt, and other materials. They’re used to either prepare surfaces for treatment or work, or as part of finishing the surface. For example, they can be used to prepare soil for roadworks and to smooth tar after application.

Rollers are also used for setting the foundation for building sites. Rollers can range greatly in size from a basic drum with a handle for individual operation to ride-on rollers with an operator dashboard and cabin. Pedestrian operated rollers include rammers and walk-behind plate compactors, while ride-on rollers include tandem drum rollers, which are vibrating rollers, and drum rollers with rubber coated drums for asphalt compaction.

What are compactors?

Compactors are machines designed to minimise the space taken up by materials, such as earth. The construction industry uses compaction equipment such as plate compactors, rollers and jumping jacks to assist with landscaping and building. For example, roller compactors are used to compact surfaces such as crushed rock so foundations can be leveled before building starts. Plate compactors use a vibrating baseplate to create a level surface, and jumping jacks are used for narrow applications such as trenches.

What’s the difference between using a compactor and using an excavator compaction attachment?

A compaction attachment is a great alternative to renting or buying a large compactor, so if you’re cost-conscious, it might be better to go with a compaction attachment instead of buying a new compactor for a specific type of work. If you already have a self-propelled roller or another piece of equipment that can accept a compaction attachment, you’ll have another reason to choose the attachment over a compactor.

If your compactor will end up sitting idle without generating a profit for you, you might be better off choosing the attachment over the whole machine. The type of work to be done should also be considered. If the attachment gives you more reach or benefits than a compactor would, choose the former over the latter. Note that another benefit of attachments might be less maintenance. If you’re bringing another compactor on your site when an excavator compaction attachment will work equally well, you’ll be doing more maintenance than you need to.

Construction site equipment features

What is a high flotation tyre?

High flotation tyres are typically used on light trucks. These specially designed tyres allow the vehicle to move easily over soft or wet surfaces without sinking in. For example, a truck fitted with high flotation tyres might be able to travel over loose sand, soft soil and mud without getting stuck. This makes high floatation tyres essential for construction and mining sites where soft surfaces are the norm.

Flotation tyres tend to be larger than other types of tyres used for light trucks, and they usually need a wider rim or wheel. Their size and width affords them more flotation, whereas narrow wheels tend to sink in soft surfaces and grip them. High flotation tyres might come with sidewall constructions, which sees them bulging out at the sides to further widen the contact area and in turn boost floatation.

What is a ROPS/FOPS/AC Cabin?

A ROPS/FOPS/A/C cabin is a cabin on earthmoving and mining equipment that meets the applicable government standards. First, the cabin needs to have Roll Over Protection Structures (ROPS). ROPS are features that protect the vehicle operator in the event of a rollover incident. The features are designed to minimise the damage to the cabin and risk of injury to the operator. Examples of ROPS structures include roll cages, bars, and hoops.

Falling Object Protection Structures (FOPS) are those that protect the vehicle occupant from falling objects overhead. Examples include reinforcements on the vehicle roof or a cage around a tractor. These reinforcements can minimise injury to the operator if rocks, branches, and other items fall on the vehicle.

Mining, forestry, and agricultural projects are some of those that need to have ROPS/FOPS cabins. A ROPS/FOPS/A/C cabin combines FOPS and ROPS features with air conditioning, ensuring temperatures inside the cabin are comfortable for the operator even if it’s sweltering outside. For mining projects and worksites during the hottest months of the year, using a ROPS/FOPS/A/C cabin on your machinery ensures work health and safety standards for operators.

What is a ROPS/FOPS Canopy?

ROPS/FOPS canopies are attachments you can add to your equipment – such as tractors and dumpers – to address risk and injury issues along with compliance requirements. Roll Over Protection Structures (ROPS) offer the operator extra protection if the vehicle rolls over by boosting the structure’s ability to absorb impact. By limiting damage to the cabin or vehicle, the risk of injury to the operator is reduced. Examples of ROPS structures include roll cages, bars, or hoops.

Falling Object Protection Structures (FOPS) are designed to shield the operator from the risks of items falling over head, damaging the vehicle, and injuring the operator. Usually this is in the form of a reinforcement installed onto the roof of the vehicle, to strength its ability to absorb the impact of something rocks or a tree falling on the roof.

If your vehicle already comes with these, you don’t need a ROPS/FOPS canopy, which combines both falling-object protection and roll-over protection. However, while some machinery will come with fully compliant ROPS/FOPS features, for other items such as dumpers you might need to attach additional elements to comply with the law.

Solution Plant Hire Related Questions

How far in advance should I book my excavator hire?

Need it tomorrow? No problem. We understand that sometimes things happen on site which you cannot predict and you need equipment, fast. We will always do our best to get you equipment when you need it, even if you call us at the eleventh hour! However always keep in mind that the better prepared for the job you are, and the more lead time you give us, the more chance you have of securing the equipment you require for the job. At the end of the day we will always do our best to get equipment to you but we are restricted by industry availability.

Do I need to pay a deposit?

Yes! Your first hire with Solution Plant Hire will require a $1000 Bond. If you do not have an account with Solution Plant Hire you will need to pay upfront the cost of the hire – we accept credit card payments. If your hire goes longer than anticipated this is not a problem – your sales rep will be in contact to arrange further payments for the hire. Talk to your sales rep for more information on if you are eligible to get an account with Solution Plant Hire.

What forms of ID are needed to hire equipment?

For all our hires we require a current Australian Drivers Licence.

Do I need a special license to hire SPH equipment?

There is no unique or specific license required for operating or hiring plant equipment.

However there are many courses available to familiarise yourself on how to operate plant equipment and we do recommend that if you are unsure of how to operate the machinery you familiarise yourself by doing one of these accredited courses. We have written a handy blog article to help you with exactly this, read here.

Is an operator provided as part of the equipment hire with SPH?

No. Solution Plant Hire specialises in Dry Hire only. In short; dry hire is the hire of any equipment with no lubricants and without an operator. Simply put you receive the equipment with all standard inclusions at Solution Plant Hire this comprises of; a modern, well maintained machine plus all your on-site paperwork taken care of, and every machine standard with all site required safety specs. We have written more information on what Dry Hire is and what is included here.

Is there a minimum number of hours required for the equipment hire?

Solution Plant Hire does hire equipment on hire by the day. We do not offer an hourly service.

Does someone from SPH have to be onsite while the job is in progress?

No. Once the equipment is on your site you are free to operate it – always keeping your safety and the safety of others front of mind. Of course don’t forget the safety of the machine also.

Does SPH have an emergency, out-of-hours contact number?

We are a 24/7 service – simply call 1300 SP HIRE (1300 77 44 73) or your sales rep directly, as our phones are always manned.

What happens if something breaks on the excavator equipment while I am using it?

As much as no one wants a breakdown – the reality is, they do happen. So if there is a problem with your equipment stop using the equipment immediately and either call 1300 SP HIRE (1300 77 44 73) or get in touch with your sales rep. They will get you back up and running as soon as possible.

If the machine breaks down onsite will a replacement machine be provided?

This will depend on the extent of the breakdown and how quickly we can get you back up and running. Each circumstance is different, but our goal is to ensure your site keeps running and you aren’t delayed. As soon as you have an issue get in touch with us and we will sort out the best solution for you.

What should I do if I can't get my equipment back on time?

Need your equipment longer? No problems at all. When you hire through Solution Plant Hire your equipment is on hire until you tell us otherwise aka offhire the equipment. If you are paying by credit card just call us up and pay for the extra time!

Am I responsible for refuelling the machines before return?

Absolutely! As we are a dry hire company only you will need to cover the costs of all lubricants.

Is insurance included in the hire cost?

No. The LTD Waiver is not insurance but it does cover you under a number of different circumstances which is covered in our Terms and Conditions of hire and you can find a copy of them here.

Is there a cancellation policy?

At Solution Plant Hire we will work with our customers wherever we can and if nothing has been mobilised such as the delivery truck or the gear is not on its way then there will be no cancellation cost. We will always do our best to avoid any costs however sometimes there are things beyond our control.

Hiring Site Dumpers

Improve your site efficiency with a site dumper from Solution Plant Hire. One of the most versatile earthmoving machines in the dry hire industry, the site dumper’s 180° swivel skip bin allows for precision backfilling and its articulation and oscillation will get you in and out of any tight spot on your job, no matter how wet the conditions.

Our entire range of site dumpers are fitted out with the latest safety equipment, guaranteeing 100% compliance. Solution Plant Hire is the only hire company in the market offering the Thwaites site dumper with low impact flotation tyres, designed for minimum ground disturbance on delicate surfaces. All our dumpers also feature certified ROPS/FOPS canopies and where relevant even air conditioned cabins.

Get a quick quote